The Last Mile’s Lasting Impact

By Amy Roach Partridge

From traditional heavy goods shipments to the new influx of e-commerce-fueled home deliveries, the last mile plays a crucial role in the supply chain. Get it wrong, and you risk alienating consumers; get it right, and you may just gain a customer for life.

LAST-MILE OPTIONS

As a result, it has become essential for companies to pay more attention to the type of shipping they offer for last-mile deliveries. Choosing from the myriad options to offer their online consumers can be challenging.

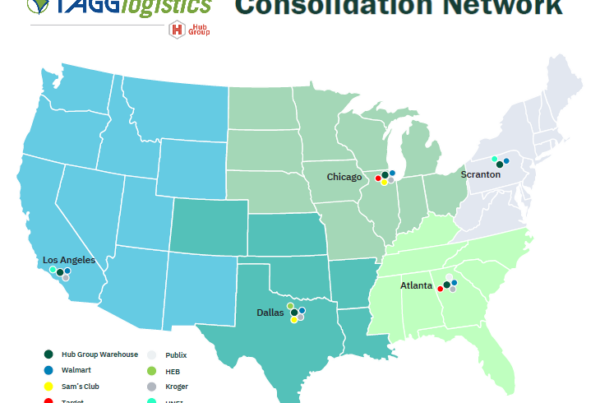

That’s where a company like Tagg Logistics can help. “We analyze how our clients handle their last-mile deliveries,” says Tod Yazdi, principal of Tagg Logistics, an outsourced fulfillment provider with facilities in Reno, Nev., and St. Louis. “We look at the type of product they ship and what the costs are, and try to pick the best carrier to deliver to the consumer’s door.”

There is also a marketing and perception value to final-mile delivery that impacts the choice of carrier, he adds. “For higher-value goods, consumers often prefer to have packages brought to their door by UPS or FedEx as opposed to having USPS leave them in the mailbox. So online shippers need to consider not only cost and time of delivery, but also how their product is perceived,” he says. “If it is a premium product, the customer will want premium delivery.”

That ability to determine which shipping methods to offer online consumers and how to handle fulfillment for last-mile deliveries is what made Scott Ohlgren, creator of a botanical-based, caffeine-free think drink called Brain Toniq, partner with Tagg.

A few months after starting the business in 2008, Ohlgren and his partner received their first shipment of about 125,000 cans, and had to store it in the partner’s barn. They did the fulfillment and last-mile shipping selection for that first shipment themselves, and soon realized they had a decision to make: purchase a forklift, rent warehouse space, and hire more employees, or find a fulfillment company to handle the process.

“I’ve seen many startups waste money doing things they should be delegating, and I didn’t want to do that,” Ohlgren recalls. “So, after researching several companies, I knew we should have Tagg manage our fulfillment and last-mile.”

The 3PL now handles the fulfillment and distribution of Brain Toniq’s roughly 250 orders per week. Each day, Brain Toniq receives orders from consumers, wholesalers, and retailers; collects them into one Tagg-specified file, tabulates the information, and by 10 a.m. the next morning sends Tagg an email with all the order data.

Tagg then processes and packages the orders, and ships them for the final mile via “the most time- and cost-effective method for each customer,” explains Yazdi.

“We use the same process for every size order— from half a case to four cases, to an entire pallet of 128 cases. It is easy for us to do, and Tagg is able to execute these tasks faster, more efficiently, and for a lower cost than we could do them ourselves,” Ohlgren explains.

Tagg also warehouses Brain Toniq’s product, receiving it directly from the brewer. The arrangement has allowed the company to keep overhead low— only four employees work in Brain Toniq’s Colorado office— while growing sales to one million cans in its second year.